We grow paulownia timber in South Carolina USA and we process the timber into paulownia wood lumber for our clients worldwide.

USA Paulownia Wood Lumber For Sale – Need paulownia wood lumber for your next project?

You will discover that paulownia wood is the “Light Strong Alternative Wood” used in many processes to obtain many varied products, not limited to:

– Construction of Boats, Kayaks, Surfboards, Snowboards, Skis, Paddleboards, Housing etc.

Weather you are a hobbyist or full time manufacturing company, paulownia wood grown in South Carolina USA may be a new expression of your talent. Learn more about our paulownia lumber here: https://bioeconomysolutions.com/paulownia-lumber/

Why should you consider paulownia wood lumber for your next project?

Properties of Paulownia Timber

1. Weight – Paulownia is a very light timber. At a dry density of around 280 kg/m³ Paulownia is lighter than most common timbers. Density comparisons are Western Red Cedar (340), Meranti (580), Pine (500), Teak (750), Robinia (750).

2. Strength – With a modulus of elasticity (stiffness) of 5.6 GPa and a modulus of rupture (bending strength) of 28 MPa, Paulownia is not classified as a structural timber in its natural state. However because of its light weight, Paulownia has a high strength to weight ratio, an important feature in the various uses of the timber.

3. Deformation & Warping – The shrinkage co-efficient of Paulownia is very low compared to most timbers being 0.094 radially, 0.268 tangentially and 0.362 in volume giving the dried timber a high level of dimensional stability.

4. Hardness – The Janka hardness rating for Paulownia is low at 1.3 kN. Western Red Cedar is rated at 1.5 and Meranti 2.6. While modern treatments can substantially harden up a finished surface, Paulownia is not suitable for flooring or areas where physical damage is likely.

5. Durability – The in-ground durability rating for Paulownia is 4 and the timber should not be used for that purpose. Paulownia used for other external uses out of ground has a similar durability to western red cedar.

6. Resistance to Decay – Paulownia is highly resistant to insect attack and rot. Research carried out by Queensland Forestry Research Institute in Australia indicates the timber to be unattractive to termites. Rot showing on neglected timber tends to be surface deep only.

7. Thermal Insulation – With one of the lowest thermal conductivities for wood of just 0.07 Kcal/m/hr/Cdeg, Paulownia has an excellent heat insulation capability being one of the best heat insulating timbers and far superior to brick, concrete or steel.

8. Fire Resistance – With an auto ignition temperature of around 400 deg C (most hardwoods around 220 deg C) Paulownia is reported to have a flame spreading rate considerably below most building codes.

9. Finishing – The sap of Paulownia is not gum or resinous based, thus the application of finishing products with various solvents as carriers does not risk any interaction with the timber, contributing to the very good finishing properties of Paulownia products. The timber readily takes stains, estapols and paints with excellent finished surfaces.

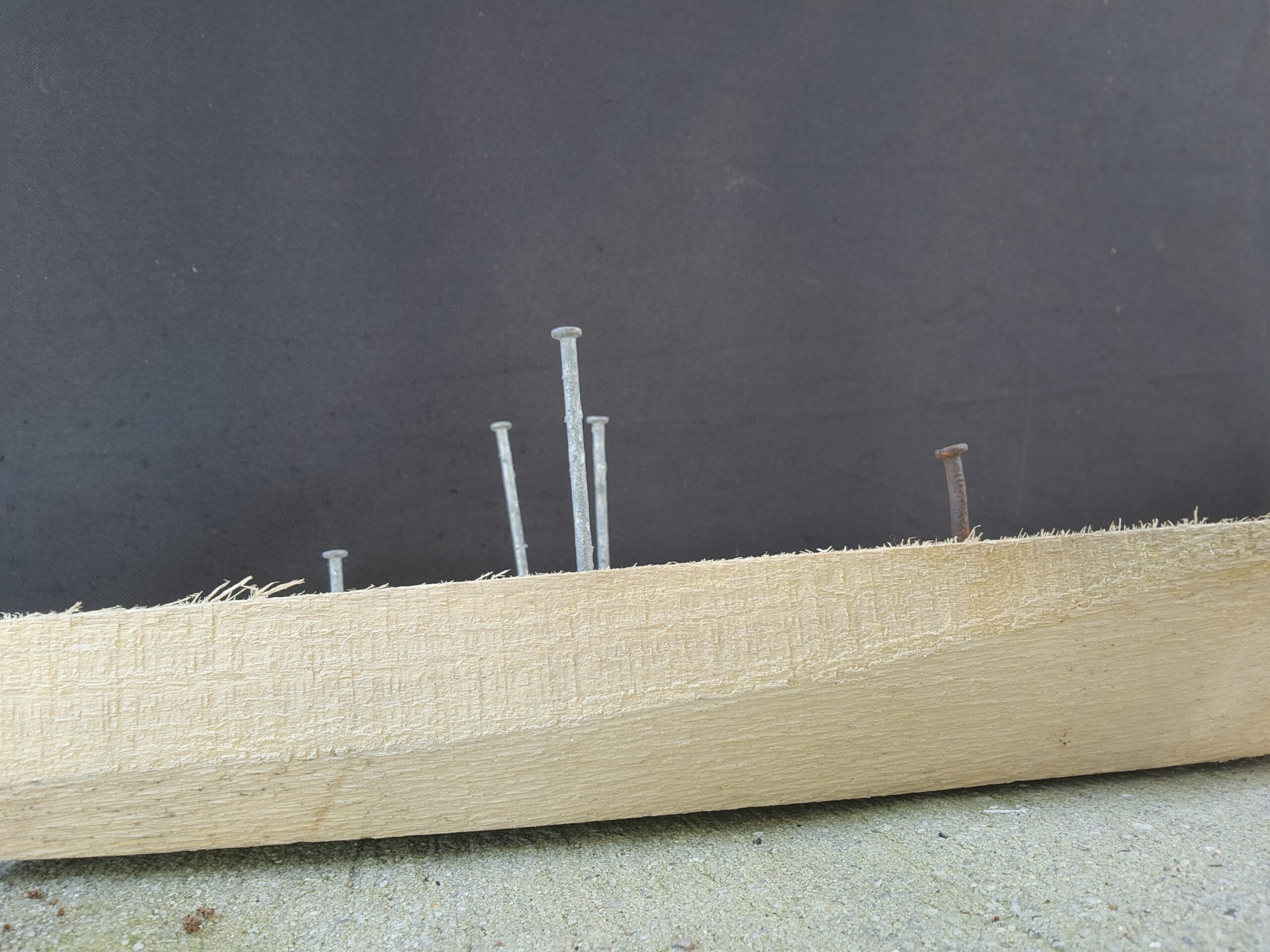

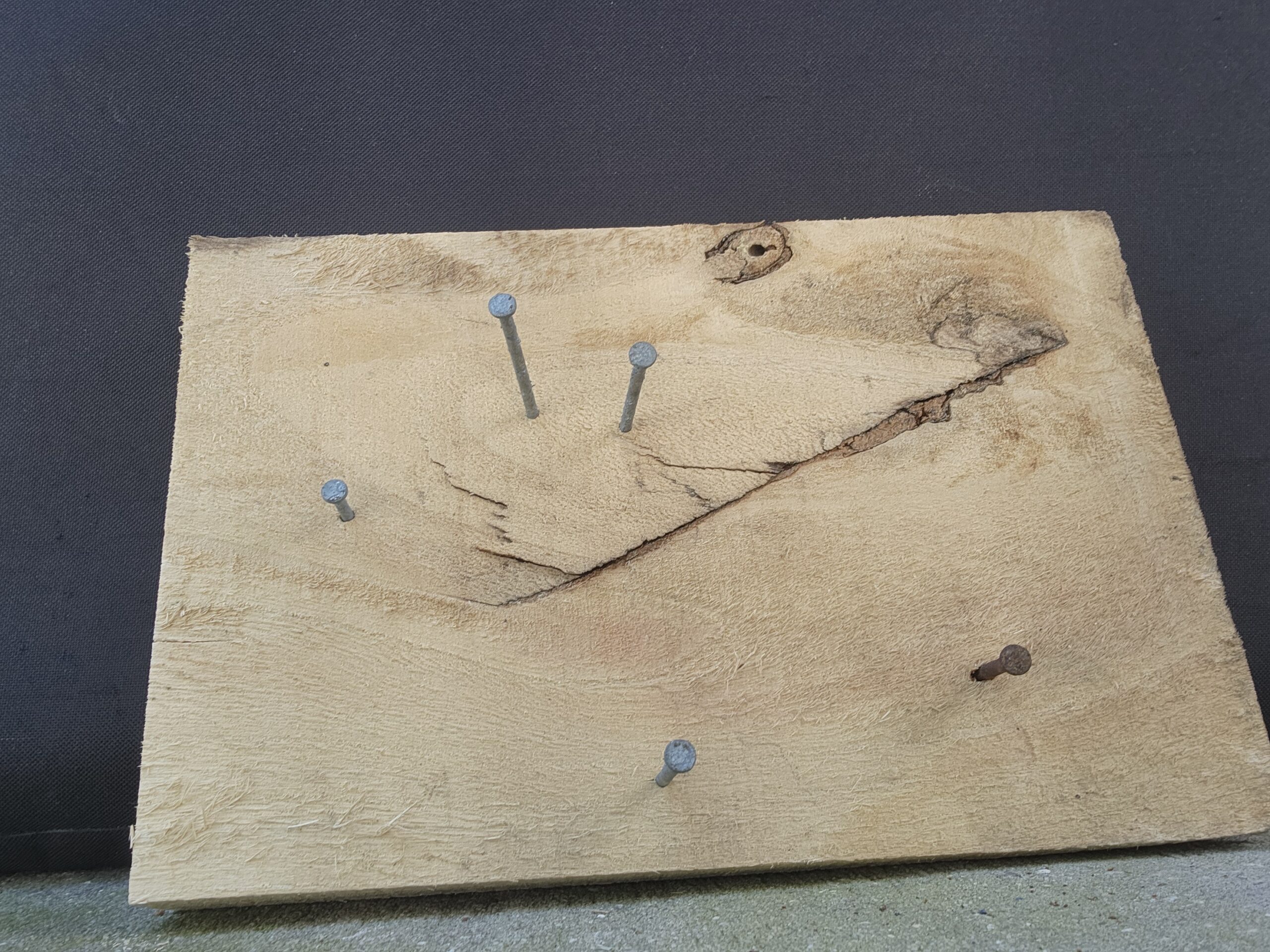

10. Workability – A major feature of Paulownia timber is its ease of working. All aspects of carpentry such as machining, nailing, screwing, gluing, sanding, sawing and handling are very user friendly with no splinters, cracking or splitting and excellent take-up of glues and finishes.

#cedar #chinesecedar #balsa #paulownia #paulowniatree #paulowniawood #paulowniatimber #kiri #kiriwood #kirilumber #kiritree #empresstree #paulowniaveneer #woodveneer #southcarolina #kiritimber #paulowniafurniture #USApaulowniawood #paulownialumber #paulowniatrees #megafloratrees #bioeconomy #investing